Solve water-related challenges for the mining industry

Water is an essential part of running and maintaining efficient mining operations. However, all mines are different. Mines are highly dynamic environments subject to frequently changing site conditions, mine plans, seasonal climatic variations as well as various other water-related factors. As a result, sustainable and efficient mine water management operations call for a thorough understanding of existing conditions and for learning from historical data to improve decision-making.

Helping you achieve sustainable water management in mining

With increasing costs related to water acquisition and management, emerging mine water risks and a commitment from industry leaders to decrease water footprints, water stewardship is at the forefront of the mining industry. By adopting sustainable water management approaches during mining activities, you can run your mine efficiently with minimal environmental impact.

An integrated water management strategy – for minimal environmental impact

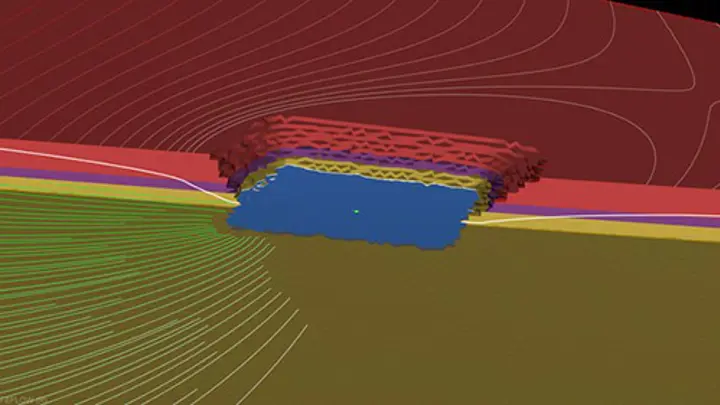

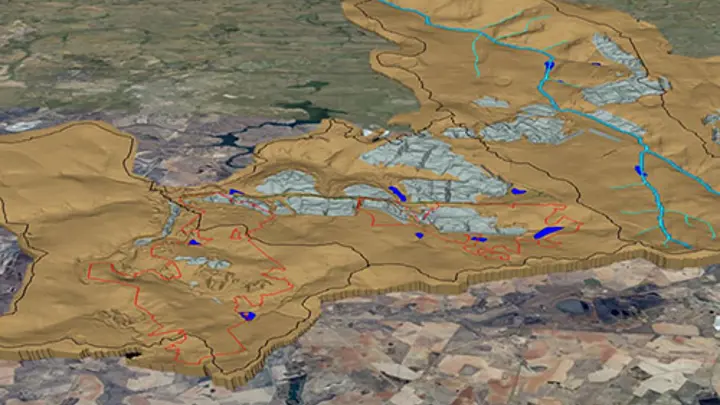

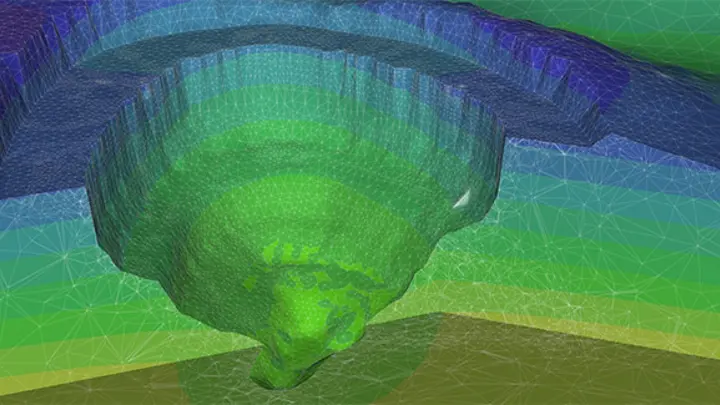

In managing mine water, we devise integrated water management strategies that cover the entire mine life cycle in a watershed context. This provides a level of reliability unachievable with traditional approaches. Using real-time data, remote sensing, online monitoring and recognised numerical and physical modelling, DHI offers a realm of digital solutions to ensure your mine runs efficiently with minimal environmental impact.

On-demand Webinar: How to unlock efficiency with MIKE Mine

Learn how MIKE Mine can revolutionise mine-water management and empower better decision-making across your operation.

Integrated solutions

Plan groundwater extraction for open-pit dewatering

Improve decisions with a mine water management plan

Determine site-wide and watershed-scale water balances

Evaluate slope stability with pore pressure analyses

Plan for the closure of a mining operation

Optimise water management approaches

You may also like

Related technology

ABM Lab

Study the impact of aquatic disturbances on habitat connectivity, migration, and populations.

Bathymetrics Data Portal

Download reliable, high-quality water depth data.

Biodiversity State Indicator

Use Biodiversity State Indicator to quantify and manage biodiversity in a holistic and transparent way.

How can we help?

With our global network of offices, we make sure you get the right answers to your local needs. Tell us about your water challenges and we will get back to you.